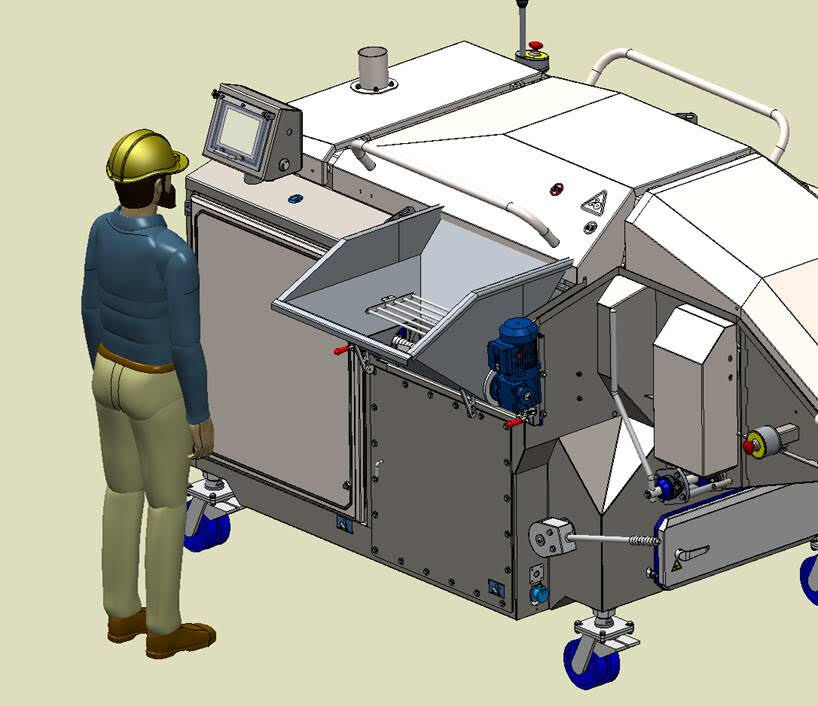

Wrightfield are the exclusive distributor of the all new Combi Coater from Symotab for UK & Ireland

The Combi Coater is a multi purpose dry coating machine

Coating can be applied in normal flatbed mode and in drum mode. The same machine will run pre-dust as well as a great variety of crumb

This makes Combi Coater the perfect machine before and after the wet coater in any convenience line.

In a flexible production line, machine configurations may need to be changed more then once a day. Replacing a flatbed machine with a drum-breader usually takes a fair bit of time and is a number one cause for damaged belts. Adjusting machine positions to create the perfect change over is also a silent cost adding to downtime.

Combi Coater Reduces manual labour and waste

- A typical line for coating elements like strips or tenders will need the sometimes sticky products to be separated and spread over the belt width.

- This is where Combi Coater in drum mode replaces manual labour and spreads each element with a firm all around pre-dust layer.

- Surplus powder is both shaken by an adjustable belt knocker and blown off during the outfeed travel. Surplus powder is recycled.

- Further more, 4 spreader arms take care that products cover the whole width of the belt ready for the next step.

Wet coating

- Wet coating is usually the next step. Viscosity control and a smooth batter or tempura will have a great impact on total pickup and final product quality.

Dry Coating

- The final step before frying is a next dry coating step. Here the second drum breader takes care of sticking as much coating material all around the product.

- The drum is 1 large 900 mm in diameter drum for a 600 mm belt width.

- In normal operation mode a whole bag of powder is present inside the drum and presses gently with considerable weight on the outside of each individual product.

- The continuous movement whereby products are lifted and spiralled to the exit end of the drum is imitating the homestyle of manual squeezing!

Simple & Rapid Changeover

- Step 1: rapid powder discharge a Shute enables standard crates to be used.

- Step 2: Operators remove the drum from the first and the third machine together with the spreader arms and drum support parts. For a trouble free lifting of the drum a unique programmed trolley is provided which helps operators to install and de-install all parts in the correct sequence.

- Step 3: Release outfeed belt tension with the external handle

- Step 4: move the exit belt from it’s low entry position to horizontal position with outside handle and extend the take over point from position 1 to position 2 with knobs

- Step 5: click the infeed belt into horizontal position

- Step 6: Close the hoods and start the machine after selecting the flatbed mode recipe for nuggets. All other adjustments are saved in one of the 75 recipes of the HMI

Summary of Features

- Fast empty mode to change to a different coating material in minutes.

- Easy and quick change-over from drum to flatbed results in wanting to use Combi Coater for more applications

- Reliable level sensor automatically keeps optimal breading level in the machine

- New led technology signalling green in normal operation mode or red in case of a drive fault

- Air knife adjustable in height, angle and direction provides perfect blow-off over the width of the belt.

- Blower is frequency driven.

-

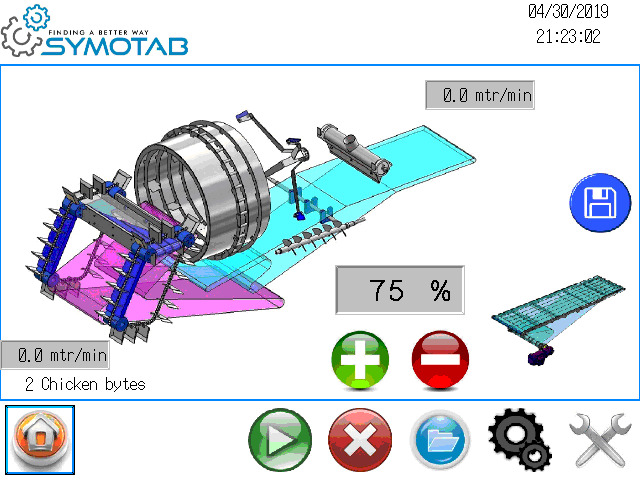

New language free touch screen where operators manage the machine by selecting various pictures. A + or – sign adds or reduces the speed of that item. Practice shows that operators understand the processes inside the machine better due to the clear pictures. It results in better adjustments and more optimal products.

-

75 recipes that can be given their own name or computer code such that operators know which program to select. The HMI also locks drum or flatbed mode to the recipe.

-

Same machines stay in same place when product changeovers are made no more a separate drum breader and separate flatbed breader or pre-duster exchanging

Contact Us About Coating Equipment

General Design Specifications

-

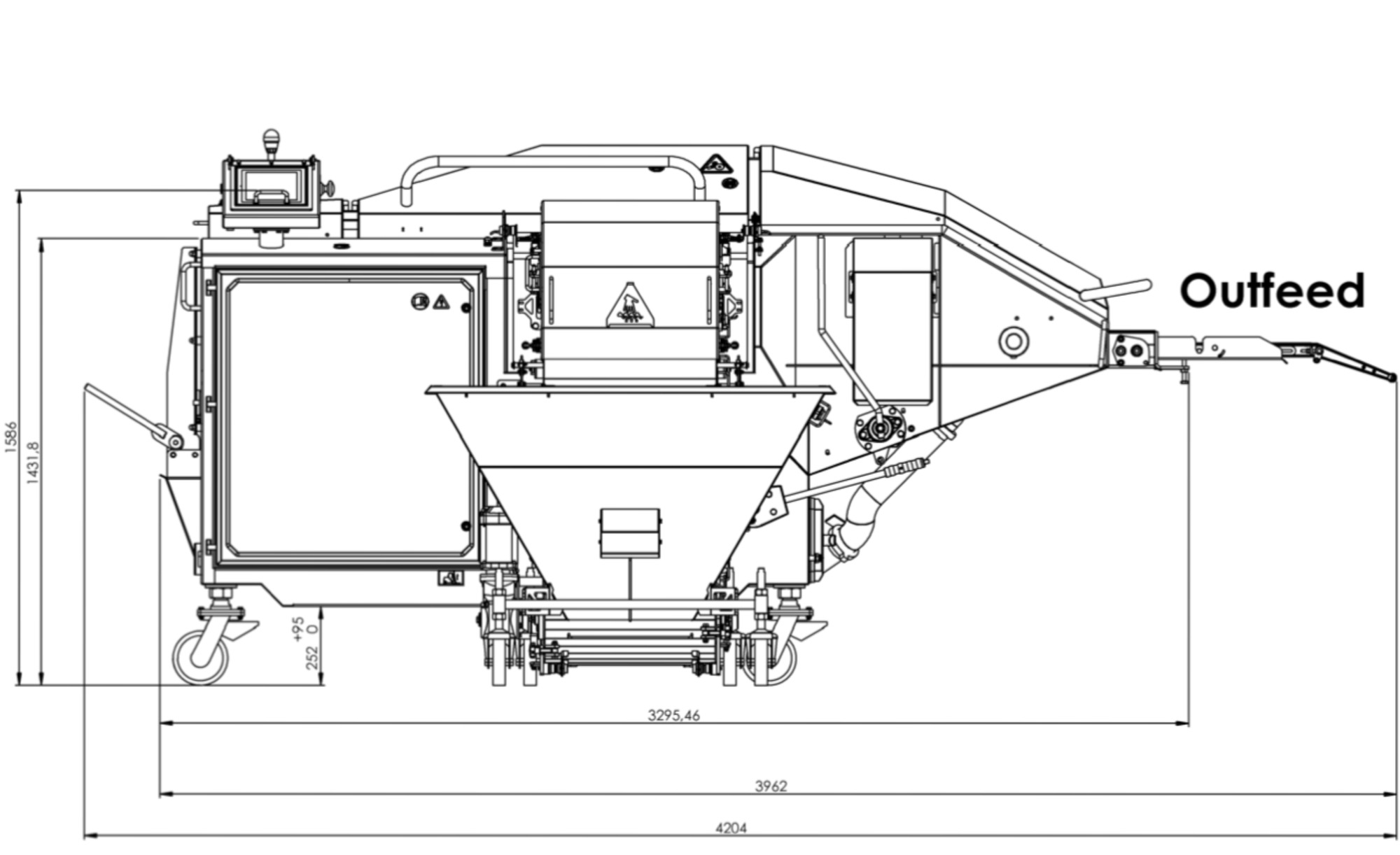

Combi Coater is metric and produced in Holland by VDL systems

-

Designed to minimize the need for spare parts

-

Total machine length is only 3.8 meters easily allowing 2 drum breaders in one line

-

Combi Coater is 2 in one.

-

Pre-dust with drum and pre-dust in flatbed mode and after wet coating there is another 2 in one Combo Coater drum breader or flatbed crumb applicator.

-

In total 4 machines are replaced by 2 Combo Coaters.

-

2 less machines to: buy, to clean daily, to move in and out of a line, to maintain and repair, to occupy production floorspace.

-

-

Changing the height of the exit belt from drum to flatbed mode moves the belt knocker together with the exit belt frame

-

Only Heavy duty top of the line SEW motors are used which can be ordered directly at SEW who guarantees 24-48 hour delivery in case of emergency

-

All components in the machine are metric and simple to order locally.

-

A unique super low consumption of spare parts

-

On board blower, frequency driven for precise per product adjustment. Air flows to the air knife through a stainless steel pipe that is easy to remove and cleaned

-

Cleaning is made easy through a special cleaning program, the drum can be moved out of the machine which makes it much faster to clean thoroughly

-

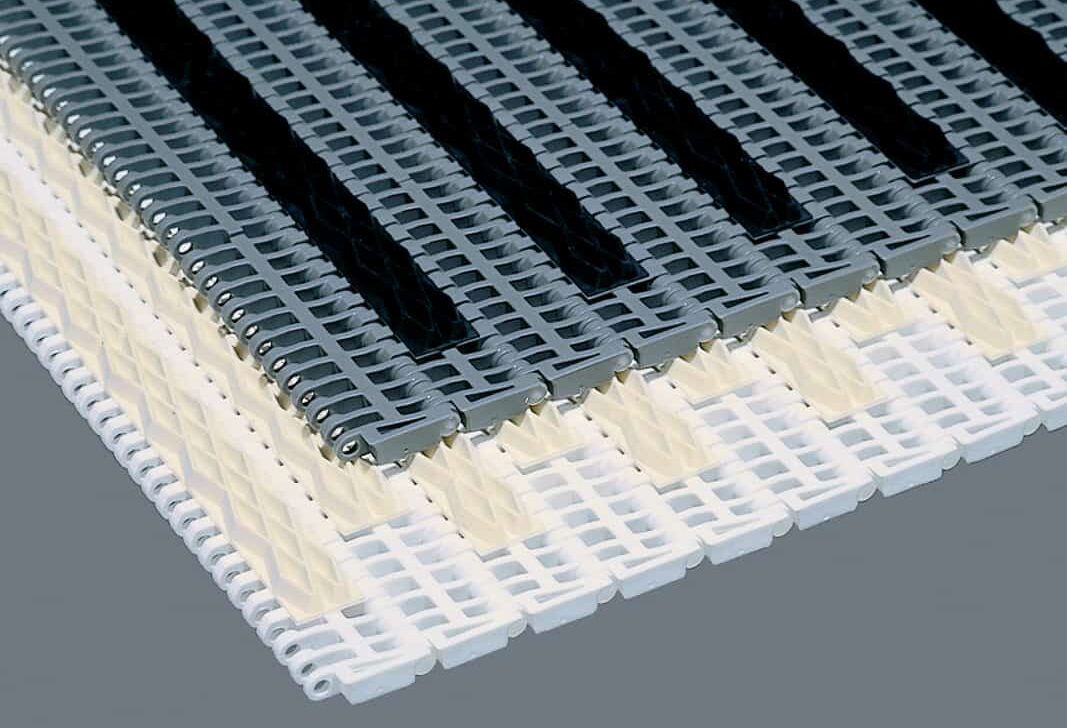

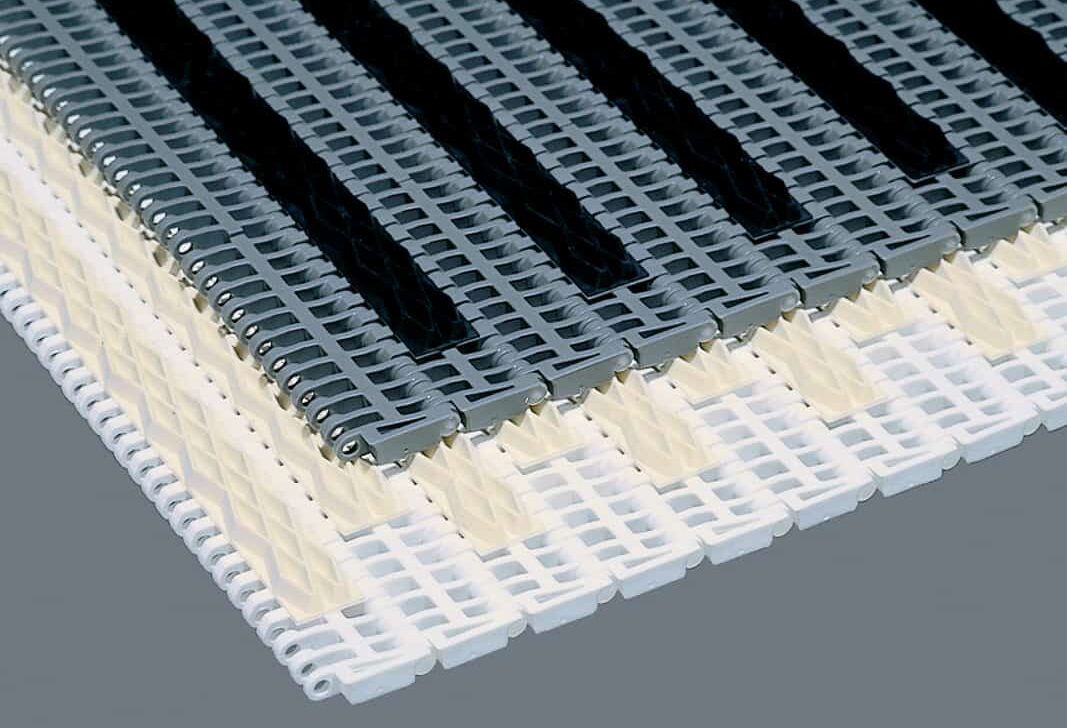

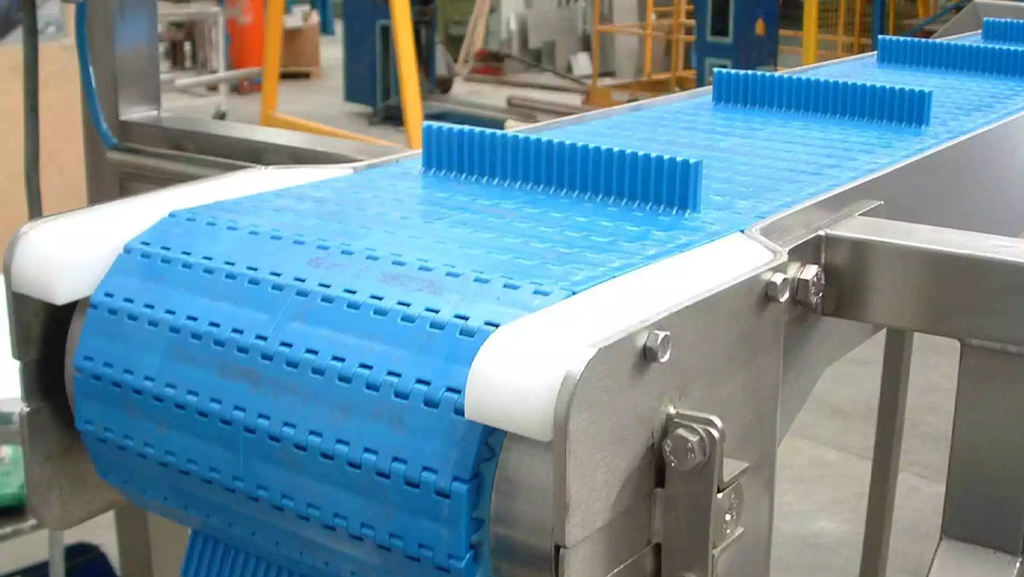

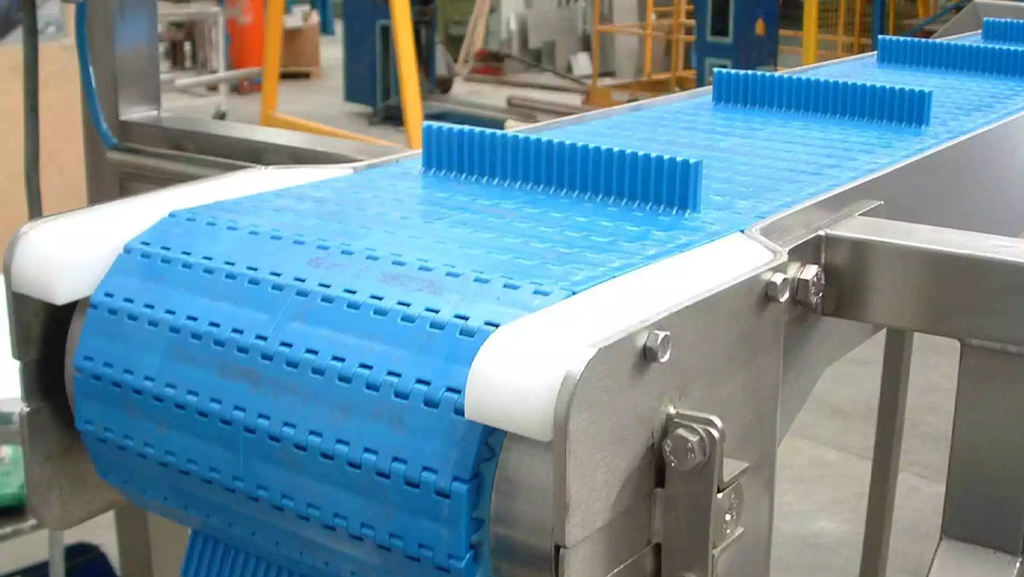

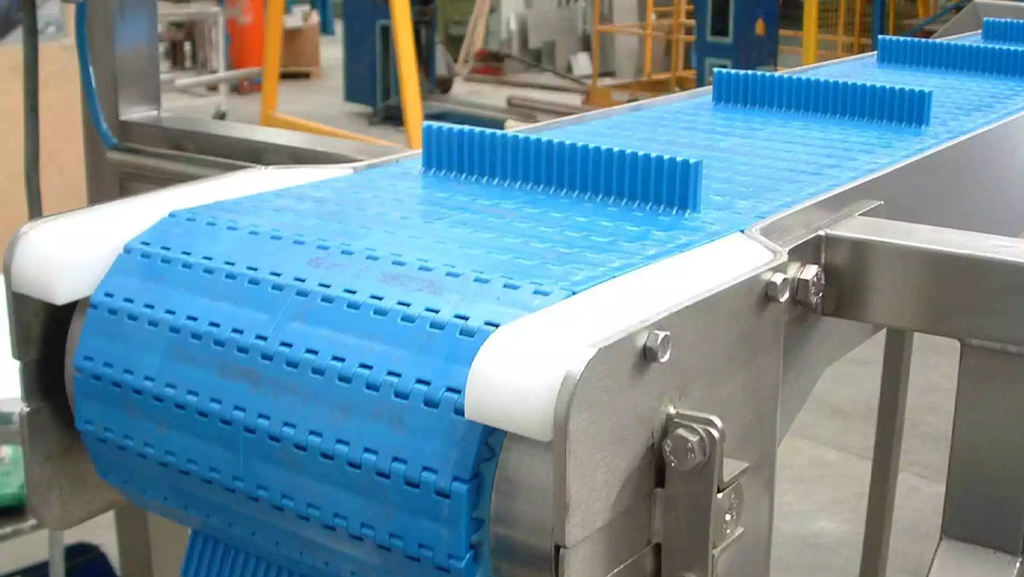

Belts for transport of products through the machine are separated in 2 and each is driven by it’s own frequency drive. It reduces wear due to stretch of the belts.

Technical details / dimensions:

- Available belt width 400 mm, 600 mm and 1000 mm. Other belt width on request.

Guarantee

- Guarantee is 24 months on manufacturing and assembly faults.

- Wear parts are excluded from guarantee.

The following brochures and data sheets are available as PDF downloads. If you would like a printed version please contact us and request

Breading & Coating Equipment Maintenance

Wrightfield offer a professional and responsive after sales service. Including both spares & various service options we can help keep your business up and running.

As partners of both Intralox (for the full range of belts) and SEW for motors, along with our ability to source from a range of manufacturers, as well as being able to manufacture or fabricate a variety of bespoke parts we are confident we can meet your needs, so why not give us a try when you next need replacement parts

We can provide planned maintenance on a scheduled basis, and well a providing skilled engineers for shift cover in the event of busy periods or holidays.

Our fully equipped vans are on call in the event of a breakdown.

Our After Sales service offerings can be bespoked to your particular requirements including:

- Mechanical

- Electrical (17th edition qualified)

- Control systems

- Belts, Motors & wide range of other purchased parts

- Manufacturing, Welding & Fabrication available in-house

- Breakdown Support

- Service Contracts

- Shift Cover

- Planned Preventative Maintenance

- Audits & Assessments

- Remote Diagnostics

Symotab Spare Parts

Belt Conveyor Components

We supply Conveyor Belting of all types including Food Grade Conveyor Belting, Grip-top Belting, PVC Conveyor Belting, Smooth. Belt Conveyor Components are available for all types of Belt Conveyors and include Drive Drums, Idler Rollers, Crowned Rollers and Motors.

- Conveyor Belting – Smooth and Grip-face belts are available to suit a variety of applications. These are available in a variety of different colours.

- Roller Drums – Drums are available to suit Wrightfield conveyors and other suppliers of belt conveyors

- Bearings – We have a range of replacement belt conveyor bearings available from stock.

- Sprockets and Drive chain – we have a range of replacement sprockets and drive chains available from stock. Non stock items can be obtained

- Knock our Rollers – We have a variety of replacement knock out rollers available. Over the years we have manufactured rollers to suit conveyors that have been manufactured but the original manufacturer is no longer able to support / supply

- Adjustable feet – We have a range of steel, plastic, steel, light and heavy duty adjustable feet available. We also manufacture bespoke feet that allow the height of a conveyor system to be raised ( which can provide a very cost effective way of adapting an existing conveyor system

- Stainless Steel Ball Units – We are able to offer stainless steel ball units.

- Geared Motor Units – We stock SEW geared motor drives for all of our conveyors, including lineshaft conveyors, belt conveyors,pallet conveyors,belt under roller conveyors and our flexible conveyors.

- Intralox – we stock a range of Intralox components

In the fast paced world of food processing, unplanned downtime owing to broken machinery can have serious consequences. We understand this and provide conveyor belt parts to help companies get back up and running as soon as possible. Because of the complete set of services we offer we are also able to provide custom built components. We discuss these topics in greater detail below.

Conveyor Belt Parts – Custom Made Components

The fact that we own our own factory is an important factor in facilitating us to provide the efficient service we do. With no middle man to deal we are able to work directly with clients enabling us to save both time and effort. Moreover, we are in a position to fully understand the requirements of a client. Finally, with our own manufacturing facility, we are able to realise a client’s objectives and to provide them with custom made conveyor belt parts if required.

Conveyor Belt Parts – Aftercare Service

We provide a comprehensive aftercare service, as part of which we supply spare conveyor belt parts and components. Additionally, the service also includes planned maintenance so as to proactively avoid any potential issues that may occur to machines, as well as offering emergency breakdown repair.

The following articles may be of interest when considering conveyor selection or operating requirements

Frequently Asked Questions on Modular Belt Conveyor Systems

1. Can modular belt conveyors be run on an incline? This depend on your product but usually up to 45 degrees can be achieved without flights…

Conveyor Systems are mechanical devices or assemblies that transport materials, components, products or food with minimal effort.

Whilst there are a numerous different kinds of conveyor systems, they usually follow a standard configuration.

Plastic modular belts are perfectly suited to going round bends and curves

They can be easily repaired ( in the event of a breakage) and extended should the need occur. This has the advantage that the plastic belts can be changed quickly.

Frequently Asked Questions on Modular Belt Conveyor Systems

1. Can modular belt conveyors be run on an incline? This depend on your product but usually up to 45 degrees can be achieved without flights…

Frequently Asked Questions on Modular Belt Conveyor Systems

1. Can modular belt conveyors be run on an incline? This depend on your product but usually up to 45 degrees can be achieved without flights…

Frequently Asked Questions on Modular Belt Conveyor Systems

1. Can modular belt conveyors be run on an incline? This depend on your product but usually up to 45 degrees can be achieved without flights…

The Combo – Coater Sanitary coating machine designed with clean-ability in mind.

- Optimal hygiene is achieved through clever features such as

- Full and luscious coverage of wet products by extra high capacity curtain ensures there will be no free liquids contaminating the machine.

- Opened drive of the curtain belt when the hood is open makes cleaning easy

Blower system rounded design and cleanable with high pressure. - Encased drive shaft of the drum sweeper arm, no motor right above product area no contamination risk

- Casters integrated in the cabinet

Intuitive Touchscreen Features:

The next step in communication with a machine in a natural intuitive way

- Spacious colour touchscreen controls all 9 frequency drives enabling perfect settings for each product stored in recipes.

- Software has fault memory, buttons to make each motor run reverse, amperage readout and other troubleshooting tools, Icons in 3D pictures on the screen are very clear for any language operator

- Safety switch recognition, no more guessing which switch is triggered, the touchscreen informs this information

Request A Demo

For more information on the Combo Coater or to request an on site demonstration please call Mark Rose on 01379 872800 or email sales@wrightfield.co.uk