Manufacture of large Chimney Stacks and Cyclones for herb production facility. Project: Camstar Herbs -…

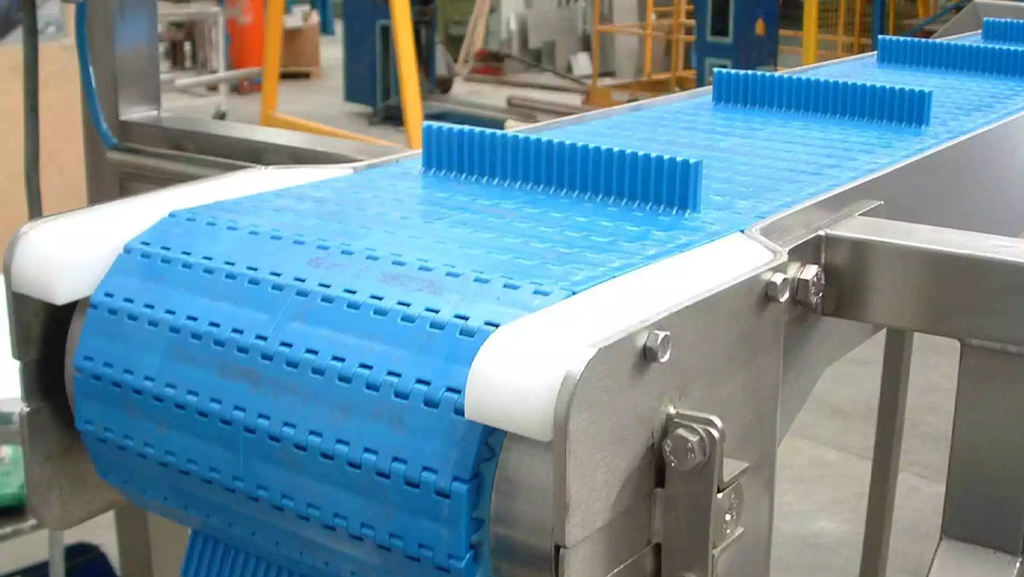

Conveyor systems are commonly used in bakery environments to transport raw ingredients, baked goods, and packaged products throughout the production process. Some specific applications of conveyors in a bakery environment include:

- Ingredient handling: Conveyors can be used to transport flour, sugar, yeast, and other ingredients from storage to mixing and dough-making stations.

- Dough handling: Conveyors can be used to transport dough through the proofing and shaping stages, as well as to transfer it to the oven for baking.

- Cooling: After baking, conveyors can be used to transport the baked goods to a cooling area where they can be cooled down before packaging.

- Packaging: Conveyors can be used to transport baked goods to packaging stations, where they are packaged and sealed for distribution or sale.

- Inspection and sorting: Conveyors can be used to transport products to inspection and sorting stations, where they are inspected for quality and sorted by size or type.

- Palletizing and shipping: Conveyors can be used to transport packaged products to palletizing stations, where they are packaged on pallets and shipped out for distribution.

Conveyor systems in a bakery environment can be made of different materials like stainless steel, aluminum, or plastic to ensure easy cleaning and sanitation to avoid contamination. They are also designed to handle high temperatures and humidity, and to withstand the wear and tear of regular use.

Weighing – Light on Losses, Heavy on Efficiency

Wrightfield understands that when it comes to bakery equipment, systems need to be accurate and reliable with little wastage. The Weighing processes are designed to ensure line speed won’t be compromised while also increasing capacity. The compatible units are easy to install and integrate as part of a bakery production line.

Conveyors – Making Dough

Conveyors are very important for allowing the whole production process to flow smoothly and efficiently, making sure that overflow or pile up is avoided. Wrightfield can design and build a number of different conveyors for site specific requirements.

Grading – Top of the Class

In the very competitive world of food production, there is always pressure to automate steps to accelerate production. Automated grading and labelling during production increases productivity.

Weighing – Light on Losses, Heavy on Efficiency

Wrightfield understands that when it comes to bakery equipment, systems need to be accurate and reliable with little wastage. The Weighing processes are designed to ensure line speed won’t be compromised while also increasing capacity. The compatible units are easy to install and integrate as part of a bakery production line.

Conveyors – Making Dough

Conveyors are very important for allowing the whole production process to flow smoothly and efficiently, making sure that overflow or pile up is avoided. Wrightfield can design and build a number of different conveyors for site specific requirements.

Grading – Top of the Class

In the very competitive world of food production, there is always pressure to automate steps to accelerate production. Automated grading and labelling during production increases productivity.

Wrightfield are able to produce bakery equipment that can accurately grade food products at high speed, enabling these products to be distributed correctly for additional processing or packaging.

Better by Design

Wrightfield’s expertise in the food manufacturing industry means that when designing bakery equipment, there are a number of important factors that need to be considered.

- Systems must be flexible, so clients can change the layout and package format quickly, as well as easily integrating and connecting to other equipment and processes in the production line.

- Being highly automated allows reduction of touch points as well as the need for manual labour operations. This makes the line more efficient to run, performing day in day out with little downtime and low operational costs for the customer.

- Hygiene and adhering to all food safety requirements is also taken into consideration when designing systems.

Bakery Equipment for Volume Production – Find Out more

Click on the following link if you would like to find out more about bakery equipment, or this link for information on other stainless steel equipment manufactured by Wrightfield.