Manufacture of large Chimney Stacks and Cyclones for herb production facility. Project: Camstar Herbs -…

General Food Conveyors info

- Food conveyors are used to transport food products in a variety of settings, including food processing plants, restaurants, and supermarkets.

- They can be used to move food products horizontally or at an incline, and can be designed to handle a wide range of food types, including raw ingredients, packaged goods, and finished products.

- Food conveyors can be made of various materials, such as stainless steel, plastic, or rubber, depending on the type of food being transported and the requirements of the specific application.

- They are typically designed to be easy to clean and sanitise to ensure food safety and comply with health regulations.

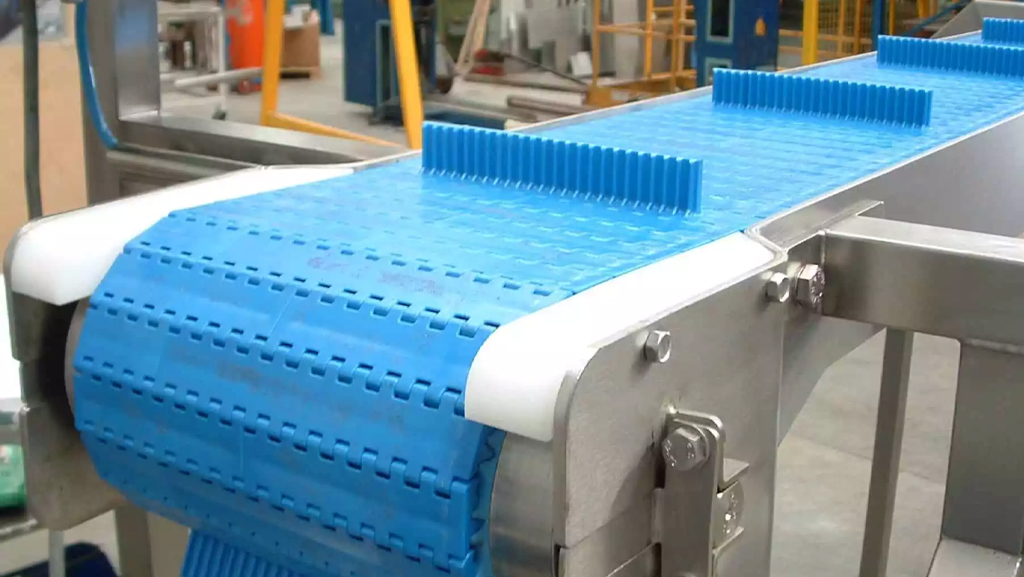

- Some common types of food conveyors include belt conveyors, chain conveyors, roller conveyors, and bucket conveyors.

- They can be powered by electricity, air pressure, or mechanical means.

- They can be used to sort, grade, inspect, package and palletize food products.

- They are also used in food manufacturing as part of a production line.

- They can be combined with other equipment like metal detectors, check weighers, and X-ray machines to increase their functionality.

At Wrightfield, we subscribe to the opinion that there is no such thing as a standard company. Nor do we believe that there are standard products. So, it stands to reason, therefore, that, in our eyes at least, standard food conveyors do not exist either. That’s why we produce a range of diverse conveyance systems to suit every business, product and need. Read on for more information.

Food Conveyors for Every Requirement

Limited Space

Limited space in a facility can present a real problem with many belts requiring a lot of room in which to operate. We offer a couple of conveyance solutions designed specifically with the capabilities required to get you out of a tight spot. The modular belt is capable of conveying items through inclined, horizontal and helical paths. The extremely flexible belt also allows for 90 and 180 degree turns. The equally flexible slat belt meanwhile, is more than capable of dealing with complex, winding routes as well as tight turns.

Multi Level Facility

If your facility operates on more than one level, you may need to transfer materials and products from one floor to another. The Wrightfield Spiral belt is more than capable of carrying out this task, as is the Elevator belt. The latter is a particularly affordable option that offers incline and decline functions as well as having the capability to perform S-bends and tight turns.

Highly Resistant

The food processing industry can cause a lot of wear and tear on a belt system. Leaked oils, grease, water and other liquids can all adversely affect a system over time, an issue that can require regular maintenance or even the replacement of an entire belt. The PU belt however, is one of the sturdiest food conveyors going, which can stand up to such rigours. The conveyance system, made from polyurethane, is also capable of handling large, heavy products and materials.

Click on the following link to find out more about food conveyors or this link for information on other stainless steel equipment manufactured by Wrightfield.