Manufacture of large Chimney Stacks and Cyclones for herb production facility. Project: Camstar Herbs -…

There are a variety of equipment that may be used in a vegetable processing plant, depending on the specific types of vegetables being processed and the desired end products. Some examples of equipment that may be used in a vegetable processing plant include:

- Washing equipment: to clean and sanitize the vegetables before processing.

- Sorting and grading equipment: to separate and grade the vegetables based on size, color, and other factors.

- Peeling and trimming equipment: to remove the outer layers of the vegetables and trim off any unwanted parts.

- Cutting and shredding equipment: to cut and shred the vegetables into desired sizes and shapes.

- Blanching equipment: to briefly cook the vegetables in boiling water or steam to preserve their colour and texture.

- Drying equipment: to remove excess moisture from the vegetables and prepare them for freezing or canning.

- Freezing equipment: to rapidly freeze the vegetables to preserve their quality and extend their shelf life.

- Canning equipment: to process and seal the vegetables in cans or jars for long-term storage.

- Packaging equipment: to package the processed vegetables in bags, boxes, or other containers for distribution and sale.

- Inspection and quality control equipment: to check for defects and ensure the quality and safety of the processed vegetables.

A vegetable processing plant is a facility in which vegetables are processed. Wrightfield is an experienced industry expert with more than 20 years working in the food processing sector. We produce a wide range of vegetable processing equipment.

Products that fall into this category that we design and manufacture include the following:

Weighing solutions – this includes fixed table weigh stations and checkweighers, both ideally suited for use in vegetable processing plants.

Grading systems – this range of versatile packaging and labelling solutions can be used to index both naked and package products.

Conveyors – the extensive range of conveyors available from Wrightfield includes spiral conveyors, transfer conveyors, elevators and multi lane & merge conveyors.

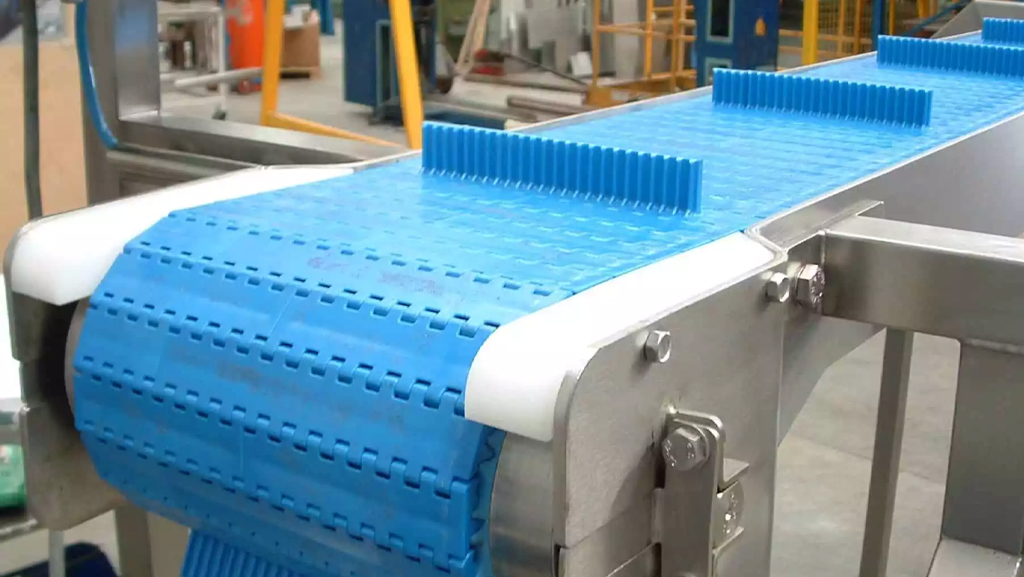

Belts – our selection of belts includes the slat belt, PU belt and modular belt. Additionally, we have the Intralox Activated Roller Belt.

Hygiene is a critical consideration when designing commercial vegetable processing equipment, as it is essential to ensure the safety and quality of the processed vegetables. Some key hygiene requirements to keep in mind when designing commercial vegetable processing equipment include:

- Cleanability: Equipment should be designed to be easily cleaned and sanitized, to prevent the build up of bacteria and other contaminants.

- Materials: Equipment should be made of non-toxic and non-corrosive materials that are safe for food contact and easy to clean.

- Surface Finish: Equipment should have smooth and non-porous surfaces, to prevent the buildup of bacteria and other contaminants.

- Seals and joints: Equipment should have tight-fitting seals and joints to prevent the entry of bacteria and other contaminants.

- Drainage: Equipment should have adequate drainage to prevent the buildup of water and other liquids that can harbor bacteria and other contaminants.

- Accessibility: Equipment should be designed to allow easy access to all parts for cleaning and maintenance.

- Temperature Control: Equipment should be designed to maintain appropriate temperatures for food safety, such as refrigeration for perishable products or heating for sterilization.

- Lighting: Equipment should have appropriate lighting to facilitate cleaning and inspection.

- Control: Equipment should have proper control systems to monitor and record the critical parameters such as temperature, pressure, etc.

- Compliance: Equipment should be designed in compliance with relevant food safety regulations and standards, such as HACCP, GMP, and FSMA.

- Maintenance: Equipment should have an easy maintenance system, with all the parts easily accessible, and the design should be such that the process downtime is minimized.

Better by Design

Our moto is Better by Design. This mantra ensures that we are constantly developing and refining our products to make them as efficient as possible. We implement the most up to date technology and employ only the latest industry best practices. Our vegetable processing equipment is designed to excel in the unique environment of a vegetable processing facility.

The solutions help to ensure the structural integrity of products throughout the processing procedure. They also help to maintain the freshness of products and keep giveaway to a minimum. We understand that every company and every vegetable processing plant is different, so tailor our products to meet the individual requirements of client.

We believe that this is the best way to achieve our aim of helping our clients to maximise their efficiency and accuracy – and ultimately their productivity and profitability.

Vegetable Processing Plant – Find Out more

Click on the following link if you would like to find out more about Vegetable Processing Plant, or this link for information on other stainless steel equipment manufactured by Wrightfield.