Manufacture of large Chimney Stacks and Cyclones for herb production facility. Project: Camstar Herbs -…

Crumbing and coating technology are used in chicken production to enhance the flavor and texture of the meat. Crumbing is the process of coating the chicken with breadcrumbs or other dry ingredients, while coating involves applying a wet batter or breading mixture.

Both techniques are used to add flavour and create a crispy texture on the outside of the chicken, while keeping the meat moist on the inside. This can improve the taste, appearance and texture of the final product.

These processes are usually done before the chicken is cooked, either by deep-frying, baking or grilling.

At Wrightfield, we design and manufacture a range of high-quality, tailored food processing solutions. Additionally, we offer a number of solutions manufactured by trusted external partners, including the Combo Coater from Symotab. We discuss this particular crumbing & coating solution in further detail in the following post.

Functionality

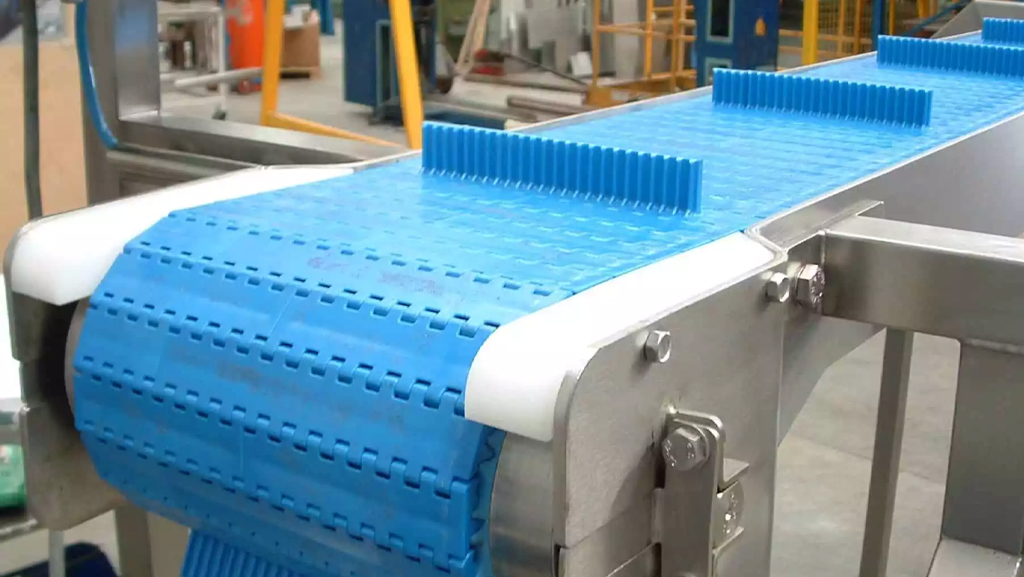

The Crumb Coater from Symotab is an extremely efficient machine that can carry out multiple functions to help a company to reduce downtime and optimise productivity.

The crumbing & coating solution is able to pre-dust and apply breadcrumbs to a product. The machine can also function as a flatbed and drumbreader.

The use of a single machine for pre-dusting and bread-crumbing is a factor that can help to reduce changeovers, idle time, cleaning costs and floor space.

Key Characteristics

- Extra wide pre-dusting curtain: this helps to provide optimal overall coverage.

- Pre-dust with drum: this ensures that products are spread evenly over the width of the belt, helping to achieve even coverage.

- Delicate handling of crumb inside the machine: breadcrumbs are lifted with scoops, eliminating the grinding used by traditional screw-type crumb transporters.

- Roller and vibrating plate: this optional extra can help to maximise breadcrumb coverage of a product.

Naturally Hygienic

These highly-functional machines are designed with cleanliness in mind. The solutions feature a number of hygienic features such as an easy-to-clean openable curtain belt drive and encased drum sweeper arm drive shaft, which helps to eliminate contamination.

Wrightfield

At Wrightfield, we are able to tailor this crumbing & coating solution to your needs, with a range of belt sizes available. We also offer a 24 month guarantee on manufacturing and assembly faults. Please get in touch to request a demo.

Crumbing & Coating – Find Out More

Automated production processes for crumbing chicken typically involve using specialised machinery to perform the crumbing process. This can include the use of conveyor belts to move the chicken through different stages of the process, as well as automated breading machines and coating equipment.

One example of an automated crumbing machine is a breading machine that can automatically apply breadcrumbs or other dry ingredients to the chicken as it moves along a conveyor belt. Another example is a coating machine that can apply a wet batter or breading mixture to the chicken using an automated dipping or spraying process.

These automated machines can help to improve the efficiency and consistency of the crumbing process, and can also reduce labour costs. Some of the main benefits include:

- Consistency in the amount of coating applied,

- Reduced labour costs,

- Increased production speed,

- Improved food safety and hygiene,

- Lowering the risk of repetitive motion injuries,

However, these automated processes can be complex and costly to set up and maintain, so it’s important to carefully evaluate the costs and benefits before investing in this technology.

Click on the following link if you would like to find out more about crumbing & coating, or this link for information on other stainless steel equipment manufactured by Wrightfield.