Manufacture of large Chimney Stacks and Cyclones for herb production facility. Project: Camstar Herbs -…

Conveyor Types

Conveyor Systems are mechanical devices or assemblies that transport materials, components, products or food with minimal effort. Whilst there are a numerous different kinds of conveyor systems, they usually follow a standard configuration. In this article we look at the multiple conveyor systems types.

- A frame that supports either rollers, wheels, or a belt, upon which materials are transported from one place to another.

- Movement is achieved by gravity, manually or powered by a motor.

- These systems for material handling should be designed to suit the different products or materials to be transported.

The most commonly used conveyors are Belt, Roller, Powered Roller, Slat / Apron, Activated Roller Belt, Ball Transfer, Magnetic, Wire Belt, Bucket, Chute, Drag / Chain / Tow, Overhead, Shuttle, Pneumatic / Vacuum, Screw / Auger, Vertical, Vibrating, Spiral, Inclined Belt, Multi Lane & Merge and Cooling Belt conveyors

In this report we are going to look at these conveyor systems in detail, conveyor system specifications and selection considerations.

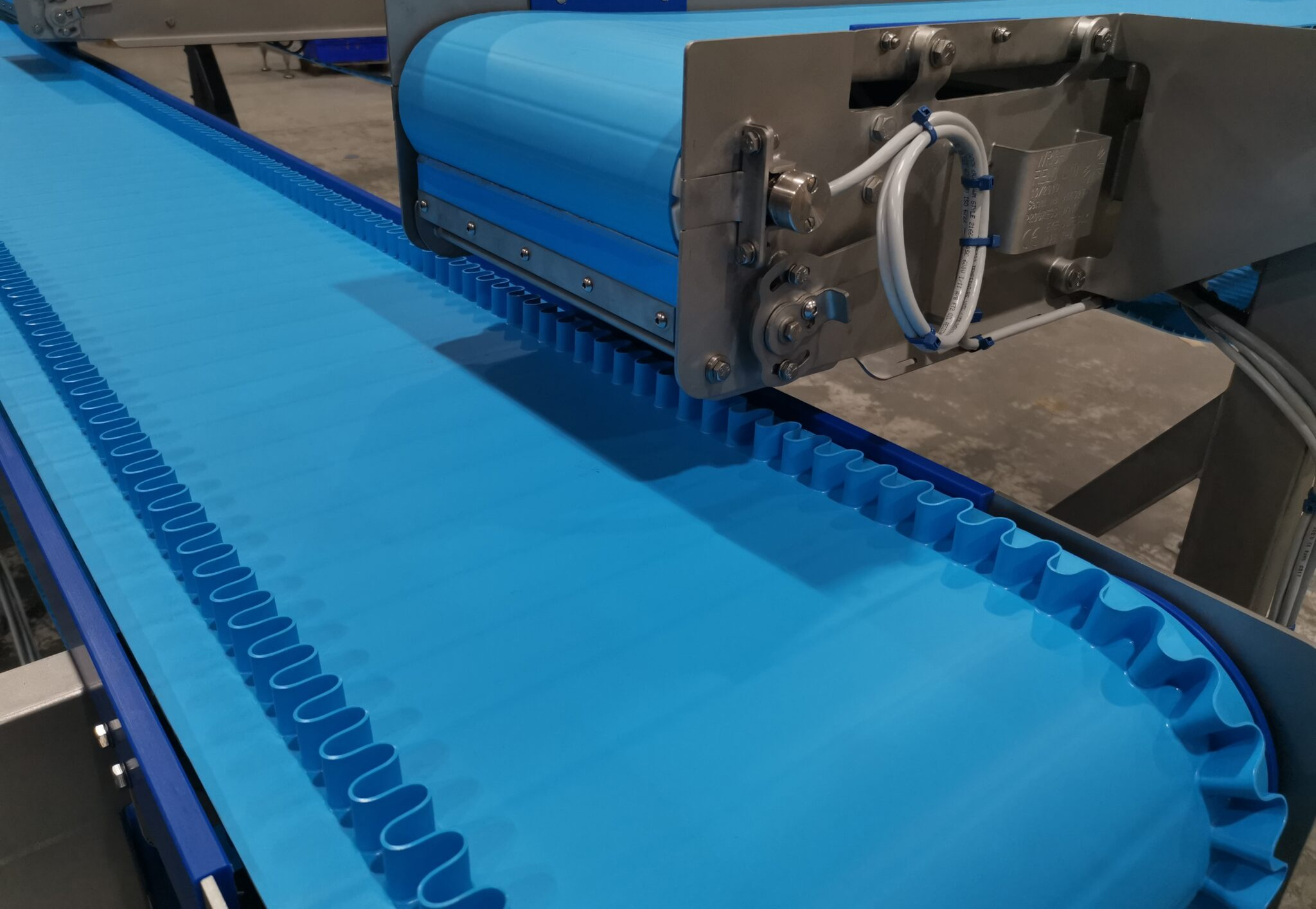

Belt Conveyors

Belt Conveyors are material handling systems that use continuous belts to convey products or material. The continuous belt is extended in an endless loop between two end-pulleys. Typically, either one or both ends have a roller below. To support the conveyor belting for light loads a metal slider pan is used where no friction would be applied to the belt to cause drag or on rollers. Motors that use either variable or constant speed reduction gears are used to power the rollers.

The conditions under which the belt will be operating, will impact on the belt material to be selected. Typical conveyor belting materials include metal, rubber, plastic, fabric, and Thermodrive. Where you are transporting heavier loads requires thicker and stronger conveyor belting material. Powered Belt conveyors can operate at various speeds depending on the production throughput required. Belt conveyors can be operated horizontally or can be inclined as well. there are important design consideration when transporting heavier / bulky items on steep inclines.

Roller Conveyor Systems

Roller Conveyors use parallel rollers mounted in frames to convey product either by gravity or manually. Key specifications include the roller diameter and axle center dimensions as this impacts on how effectively items will be conveyed. Primarily used in material handling applications such as on dispatch areas, assembly lines, loading docks, and baggage handling plus many others. If inclined the rollers use gravity to transport the item ( the angle of incline needs to be carefully evaluated) , if mounted horizontally then manual force is required to help the item along the conveyor. Depending on the application and available floor space conveyors can be straight or curved.

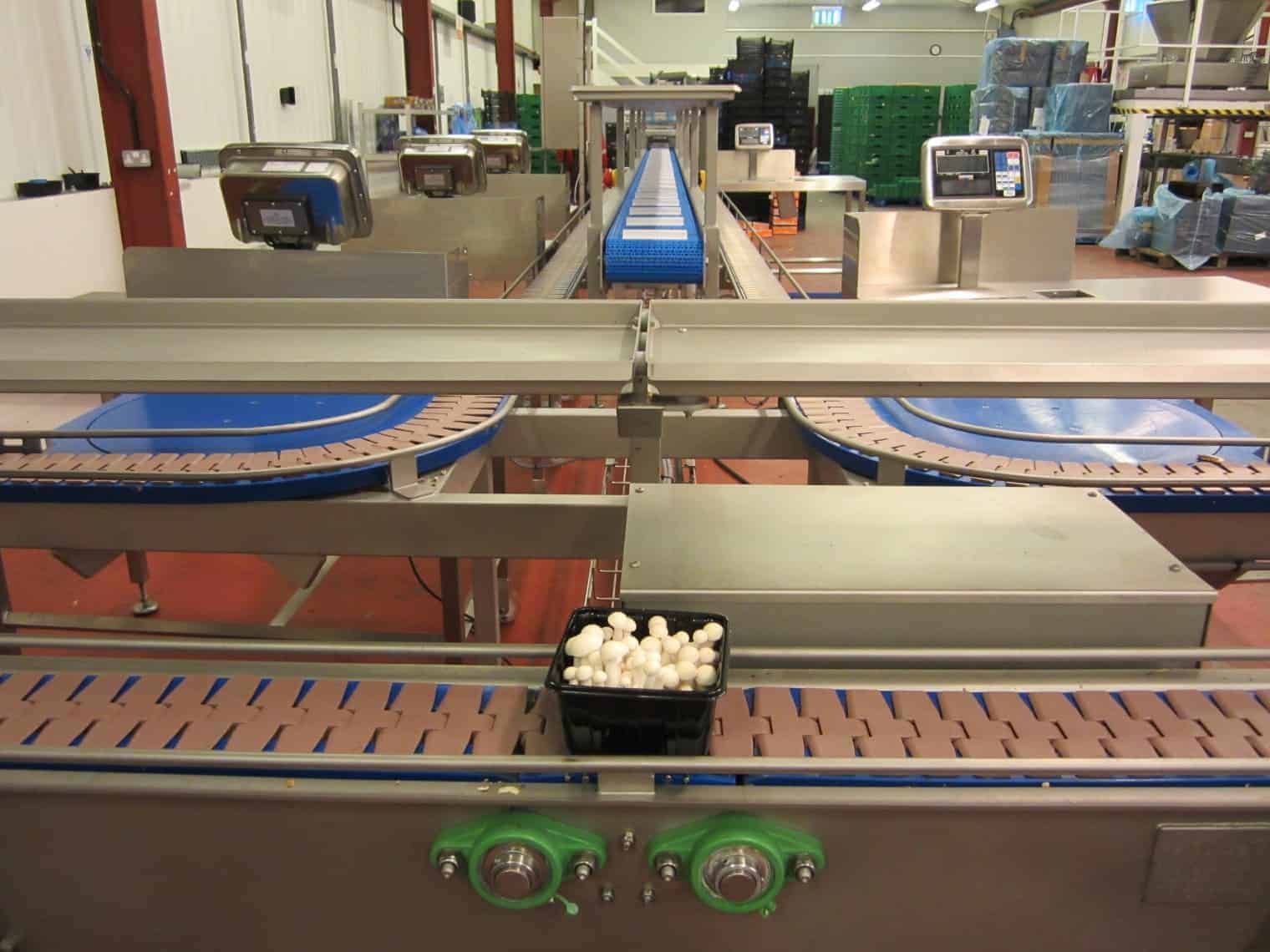

Powered Roller

Powered Roller Conveyors use powered rollers mounted in frames to convey products. Along with roller diameter and material and the axle center dimension the other key specification criteria is the drive type. Primarily used in material handling applications that require the powered conveyance of the product. Powered roller conveyors used various drive types including motorised rollers, belts, chains & sprockets. Powered roller conveyors can be found operating in are food handling, packaging and other environments.

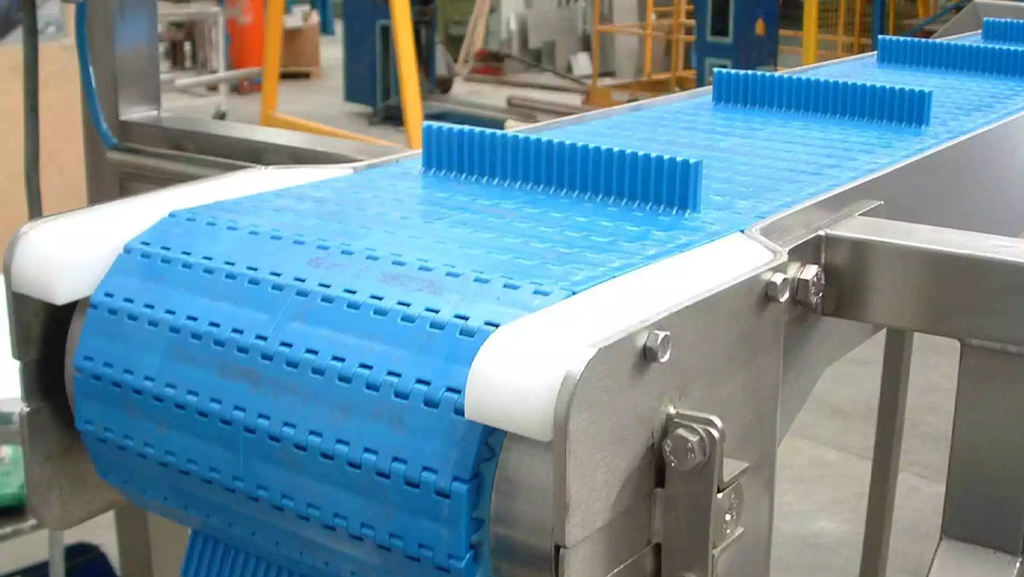

Slat Belt Conveyor

Slat conveyors are a type of conveying technology that uses a chain-driven loop of slats to move product from one of its ends to another. A motor drives the chain, which causes it to cycle just as belt conveyors do. Instead of a rubber belt, this conveyor type uses slats connected to a chain, providing a rigid, flat surface for every item on the conveyor. This makes slat conveyors ideal for irregular shaped products that cannot / are unsuitable to be used on rollers or belts . These conveyor systems are usually powered and come in many sizes and load capacities.

Ball Transfer Conveyor

Ball Transfer conveyors ( sometimes called ball transfer tables) use a series of mounted ball casters to allow for multi-directional (360 degree) , unpowered, conveyance of the product. The ball material and diameter size are the key specification elements with many sizes and load carrying capacities being available. Used predominantly in material handling applications such as assembly lines and packaging lines, they are often used where multiple conveyor lines meet to transfer products from one line to another. . Ball transfer conveyors rely on external forces ( i.e. manual operation) to move the product along the conveyor.

Bucket

Bucket Conveyors or bucket elevators use multi-sided containers attached to cables, belts, or chains to convey products or materials. The containers remain upright along the system and are tipped to release material. Bucket conveyors are used in applications such as parts, bulk material, or food processing and handling. The conveyed material can be in liquid form or dry such as sludge, sand, manure, sugar, and grain. The systems can be used horizontally or can be inclined or vertical to change levels of the delivered products. Many sizes and load carrying capacities are available depending on the application.

Chute

Chute Conveyors ( sometimes called Trough Conveyors) are material handling systems that use gravity to convey product along smooth surfaces from one level to another. A common use of chute conveyors is for scrap handling, postal service, packaging, package or mail handling, etc. where chutes are designed to be slippy having a low coefficient of dynamic friction. This allows products or materials to slide easily, down the straight or curved conveyors. The chute material and the physical dimensions such as length and chute width are key specification elements.

Pneumatic/Vacuum

Pneumatic / Vacuum Conveyors use air pressure or vacuum to transport materials or items in or through closed tubes or ducts or along surfaces. They are used primarily in materials handling applications such as dust collection, ticket delivery, paper handling, etc. and in processes such as food, chemical, mineral and scrap. Materials for the pneumatic conveyors can be non-metallic or metallic depending on the product being conveyed. As with most other conveyors various sizes are available depending on the load and throughput requirements.

Free Conveyor System Technical Audit

Get In Touch For Advice And A Quotation

Conveyor Systems Types Selection Considerations

When deciding on which conveyor system best suits your needs, there are a number of key considerations these include

1: Material being transported

- Some important characteristics to consider are

- size,

- flowability,

- abrasiveness,

- corrosiveness,

- moisture content,

- and the temperature at which it must be kept.

- The composition of the material, if powders, granules, pellets, fibres, or flakes are being conveyed,

- The particle size, weight, and density.

2: Conveyor Function (Conveying & Feeding)

The two main categories of moving material through a process are conveying and feeding.

- Conveying is the moving of materials from one or more pickup points to one or more drop points.

- How much time for this movement should be considered,

- As well as the number of pickup and drop points,

- The amount of material being moved,

- Is cross-contamination between multiple materials is a concern.

- Feeding is more time sensitive and requires more precise systems than coveying. Material is usually moved from one pickup point to one drop point. The product being moved may have to be delivered in batches, or at a controlled, continuous rate.

3: Conveyor Environment

- An essential factor to consider before the selection of a conveyor system is the environment in which it will be used.

- Determine any potential risks such as high humidity, temperature, vibration, pressure, fragile or hazardous materials, and flammable products in the facility with a conveyor manufacturer to identify the countermeasures and workarounds needed.

- The physical size and shape of the system compared to how much room in the workspace is available should be considered, along with how it will fit alongside existing equipment.

4: Conveyor system design

Owing to their large scales and integration into different factory processes, conveyors systems are often relatively complex in their design and construction . Fortunately, the modular nature of many conveyor components makes even complex and long conveyor systems easily achievable. Manufacturers of such systems like Wrightfield can offer design assistance so that the conveyor suits the workspace.

5: Preventing Product Slip

High friction belting, buckets, cleats etc. are common forms of preventing product slip in circumstances a heavily loaded inclined belt conveyor can slip backward when the drive is off. Backstopping brakes that engage automatically with de-energization of their motors are often used to prevent this. The releasable brake allows the conveyor to reverse for unloading prior to servicing. A certain amount of slippage is desirable in some conveyors, for example those handling glass bottles on packaging lines.

6: Static Electricity In Conveyors

As the conveyor belt is continuously pulled against the end pulleys, conveyor belts are susceptible to static electricity. If electrical / electronic components are being conveyed, static electricity can be hazardous. Anti-static conveyor belt measures such as static control brushes or conductive belts are available to protect products.

7: Conveyor Safety

Where long conveyor lengths are close to personnel other safety elements must be considered. Options include

- Pop-out rollers that disengage from their drive belts if a person’s foot or hand slips between rollers.

- Crossovers can be used to permit people to pass over long sections of belt conveyors.

- A soft starter or clutch mechanism is fitted to avoid overloading motors when starting fully loaded belts, chains, etc.

- Using geared motor drives that incorporate internal motors and gear drives within the head rollers eliminates the need for externally mounted motors and power transmission components.

Free Conveyor System Technical Audit

Get In Touch For Advice And A Quotation

Important Conveyor Systems Specifications

Load Capacity per Unit Length : this attribute is used in cases where the conveyor will be built to a custom length to permit users to determine loading margins.

Maximum Load Capacity ( also known as flow rate) : Associated with Load Capacity per Unit Length, this value can be stated for fixed length, purpose-built conveyors.

Conveyor Belt System Speed/Rated Speed:

- Belt conveyors are typically rated in terms of belt speed in m/min ( ft/min ).

- Powered roller conveyors describe the linear velocity in similar units to a package, carton, etc. moving over the powered rollers.

- Rated speed applies to apron / slat conveyors as well.

Throughput: Throughput measures the capacity of conveyors that handle powdered materials and similar bulk products. It is often given as a volume per unit time, for instance, as cubic feet per minute.

Frame configuration refers to the shape of the conveyor frame. Frames can be straight, curved, z-frames, or other shapes.

Drive Location: On a conveyor system drives can be located in different places.

- A head or end drive is found on the discharge side of the conveyor and is the most common type.

- Centre drives are mounted underneath the system and are not always located at the actual centre of the conveyor. They are used primarily for reversing the direction of a conveyor.

Conveyor Systems Types More Information

More information on conveyors and conveyor systems can be found in the following articles

For more information on Stainless Steel Conveyor Systems click here to see other examples of Stainless Steel Pools click here