Manufacture of large Chimney Stacks and Cyclones for herb production facility. Project: Camstar Herbs -…

In the food processing industry, conveyor belts are of the utmost importance. Indeed, companies in the sector quite literally run on them. Here, we take a look at what to look for when selecting a belt, as well as providing information on the selection of belts manufactured by Wrightfield.

Reliability Is King

When it comes to conveyor belts, reliability is king; after all, unplanned downtime can have serious consequences. A conveyor belt should offer at least some versatility, with enough robustness to handle a range of products of varying size and weight.

It can also be very beneficial for a conveyor belt to be resistant to liquids like water, oil and grease, many of which are found in the food processing industry. Any conveyance solution should also be resistant to industrial strength cleaning products, this will help to ensure that the high levels of hygiene required when processing food can be maintained.

Wrightfield Belts

There is a comprehensive range of conveyor belt types available from Wrightfield. Many of the belts that we offer can be manufactured to the specifications required by a client, such as bespoke lengths and widths.

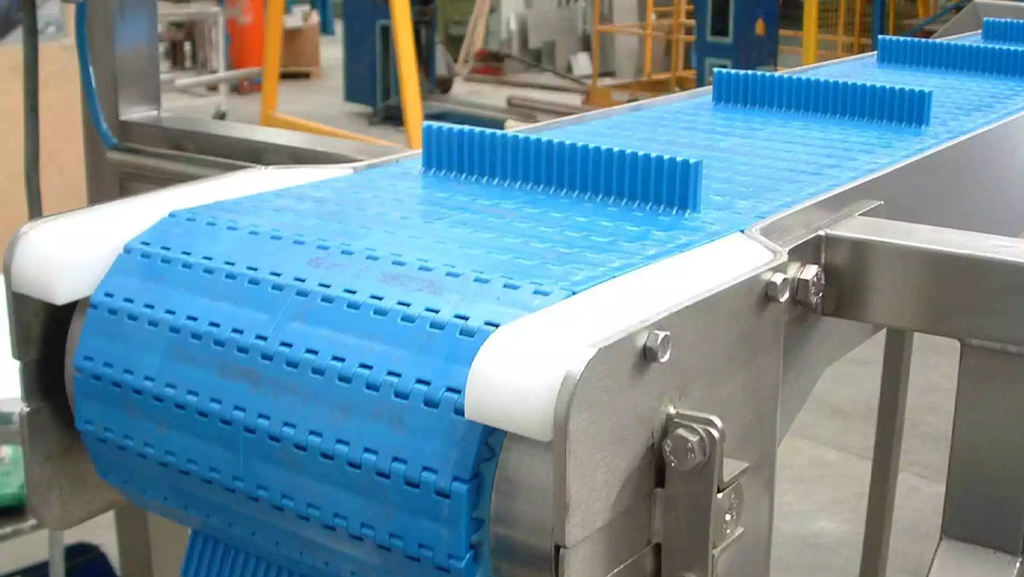

Modular Belt

Made from FDA approved materials, the modular belt is a conveyance solution that is very well suited to the food processing industry. The belt is very flexible and able to convey products through inclined, helical and horizontal paths.

This flexible conveying solution is able to convey products through inclined paths, as well as horizontal and helical paths. Moreover, the belt is very flexible and permits 90 degree and 180 degree turns.

These attributes make these types of conveyor belts well suited to winding routes. The modular belt is an extremely reliable and versatile conveyance solution, having been tried and tested in a variety of disparate environments and situations.

Key features

- Available in lengths and widths to suit all applications

- This belt is very low maintenance

- Made from FDA approved materials

Conveyor Belts – PU

The versatile PU belt (also known as the polyurethane belt) is designed with durability and robustness in mind. Resistant to the highly abrasive cleaning products often used in the food processing industry, this belt provides plenty in the way of hygiene.

The polyurethane belt (also called the PU belt) is a versatile belt that is used across a number of different industries. The belt is capable of conveying all manner of products, from delicate food substances to large boxes.

The PU belt is one of the types of conveyor belts that is particularly well suited to the food industry, this is in part owing to its resistance to liquids, such as grease, oil and water. Furthermore, the belt is resistant to the highly abrasive cleaning chemicals that are regularly used in the food industry.

Key Features

- This belt is made from high resistant materials

- The belt is designed to deliver durability and robustness and to provide high levels of hygiene

- Available in specifications tailored to the needs and wants of the customer

Conveyor Belts – Slat

With an innovative hinge design, the slat belt is easily able to handle complex loops and tight corners; ideal if a facility is a little short on space. The belt is generally used to convey smaller, lighter duty items.

Owing to its hinge design, the slat belt is extremely flexible, and able to handle complex loops and tight corners. This makes the slat belt suited to facilities in which space is at a premium. This type of belt often used to convey smaller, lighter duty items.

Key Features

- Extremely flexible

- Suited to long, winding routes, such as those one may encounter in a bottling plant

- This belt can be used for overhead conveying

Conveyor Belts – Find Out More

Click on the following link to find out more about conveyor systems or this link for information on other stainless steel equipment manufactured by Wrightfield.